What types of probes are used with in-line spectrophotometers?

An in-line UV-Vis spectrophotometer enables real-time process monitoring and control. When using an off-line laboratory spectrophotometer, a sample is taken from the process, molded into a plaque, and inserted into the lab instrument, where an energy source focuses light onto the sample and a detector receives and measures the reflection, transmission, or absorption from the partial energy received. For an in-line spectrophotometer, however, unique fiber optic probes are needed to bring light energy to the process and return the received light to the detector. These probes, inserted into the plastic process, are designed to withstand the harsh conditions of the manufacturing environment.

To learn more about spectroscopy, visit Equitech’s Knowledge Center to read about color measurement and how a spectrophotometer works.

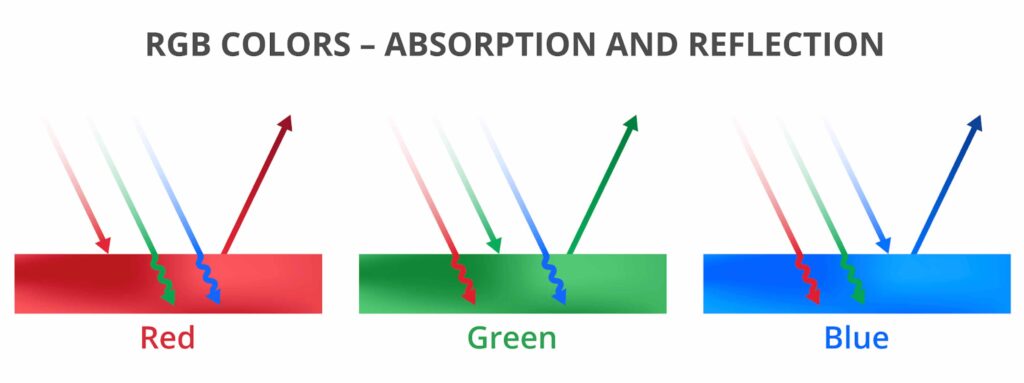

Transmission vs. Reflection

When light strikes an object, some light energy is reflected (the red wavelength in the diagram), and some is transmitted (the green and blue wavelengths in the diagram). A spectrophotometer can operate in transmission or reflection modes to detect transmitted or reflected light. The calculations performed by the associated software use the appropriate equations for either transmitted or reflected light. An in-line spectrophotometer may use a different configuration for the probes used to measure transmission or reflection, as discussed in the last section of this article.

Placing the probe in the polymer melt

In-line probes can be designed as “non-contact” (near, but not touching, the polymer) or as “contact” (directly in the molten polymer). For example, a non-contact probe enables the measurement of color of an extruded sheet without scratching it. However, a contact probe that measures color directly in the polymer melt must be specially designed and placed so that the lens has a clear view of the polymer as it flows past the probe. The probe should be put into the melt where the shear rate of the material flow is high enough to minimize the risk of material coating the tip. This self-cleaning function is essential to keep the lens clear for light transmission and detection.

Choosing the proper probe

Equitech’s In-line Process Spectrophotometer (IPS) measures color in-line in real-time, directly in the polymer melt. Equitech manufactures over 10 contact and non-contact probes that measure solids, liquids, slurries, pastes, polymer melts, and gases. In addition, Equitech invented the Reflection Polymer Melt Probe (RPMP) for in-line color measurement of extruded thermoplastics. The RPMP is ideal for measuring opaque molten polymers. It has six illumination fibers evenly spaced around the probe circumference and a single fiber to receive the reflected light.

The probe fits into the standard extruder port typically used for temperature or pressure transducers. In addition, the RPMP’s sapphire lens—second in hardness only to diamond—resists damage or scratching, and the “self-cleaning” design prevents material build-up on the lens.

Undispersed, solid particles in the melt could interfere with the measurement by refracting the light. The Equicolor software can account for this measurement error for an occasional undispersed particle in the molten polymer. Still, if the amount of solid particles is high, it will be detected as a color change. In this manner, the IPS can detect problems in the feeders or due to changes in the raw material or processing equipment.

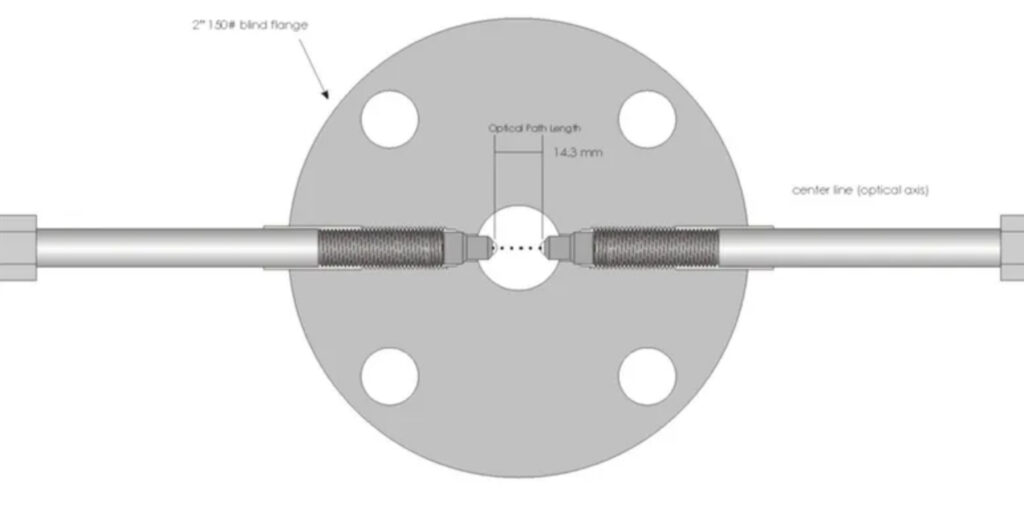

For transparent and translucent molten polymers, the Transmission Polymer Melt Probe (TPMP) configuration uses one RPMP as an illuminating probe and another RPMP as the detecting probe. The distance between the lenses—the optical path length—can be optimized to meet the needs of a process. If the gap is too large, inadequate light may be transmitted, or variations in the polymer’s optical characteristics can create instability. If the gap is too small, measurement sensitivity to changes may be reduced.

Contact Equitech’s experts to learn more about how an in-line process spectrophotometer can benefit your operation and determine the probe best for your application.