fiber optic probes

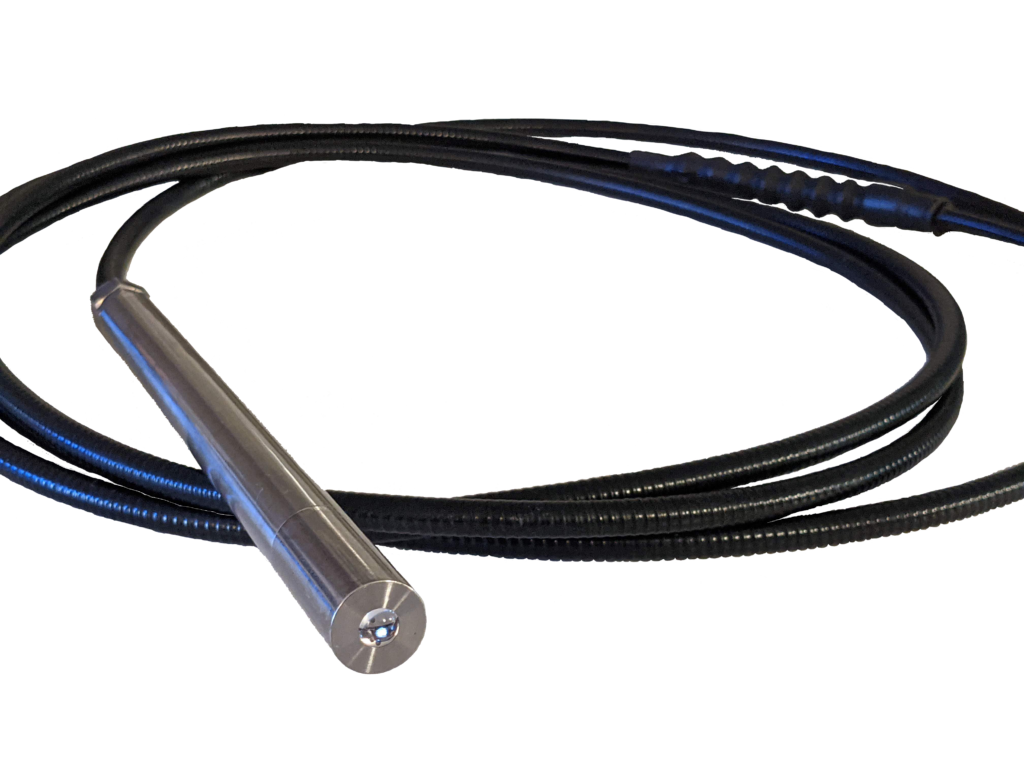

Fiber optic probes have two main components: a fiber optic cable and a probe body. The fiber optical cable houses two or more optical fibers that are grouped, routed, and shielded. This cable is terminated through a probe body, which is the interface to the sample of interest, using a specific opto-mechanical design. Let’s examine these components closer.

Optical Fibers

An optical fiber is a thin, long, flexible glass rod used to transmit light from one end of the fiber optic cable to the other. Due to this capability, fiber optic probes can be manufactured to sense and measure material characteristics for many applications. Since optical fibers transmit and receive light, this enables fast, precise, and non-invasive measurements in challenging environments.

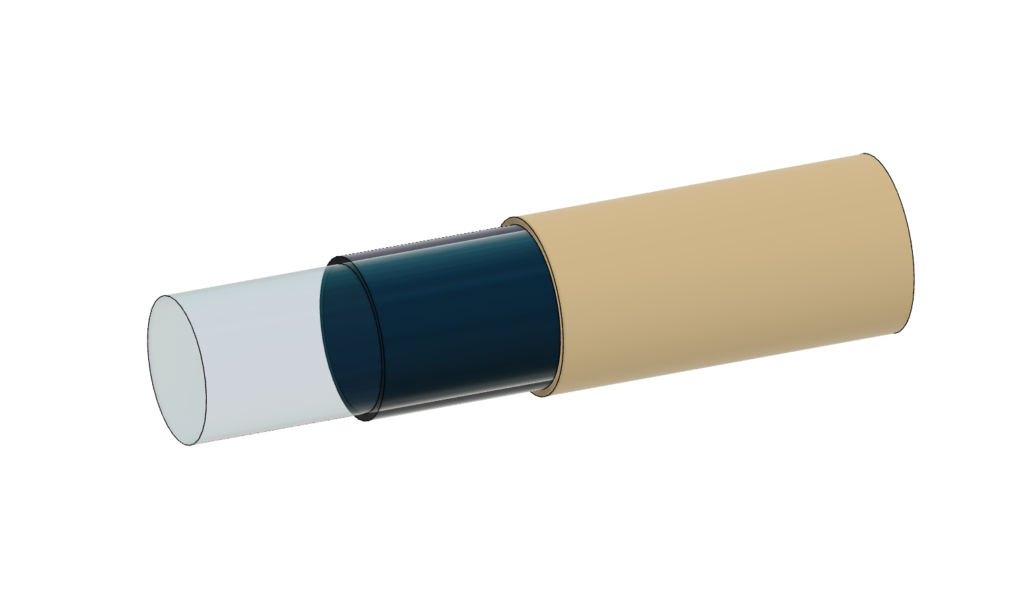

Optical fibers are made of three parts: the core, the cladding, and the coating. The core, made of glass, is the center of the fiber, and it carries the light signal. A transparent cladding material with a lower index of refraction surrounds the glass core. The cladding keeps the light within the fiber’s core, which is achieved thanks to a phenomenon called ‘Total Internal Reflection’ that causes the fiber to act as a waveguide. Finally, the outmost layer, called the coating, protects the cladding.

Two significant categories of optical fibers are glass optical fibers (GOF) and plastic or hard-clad silica (PCS/HCS). For GOF, the core and cladding are made of glass. However, while the core is silica (doped with metals to increase the refractive index), the cladding is usually made of pure silica or fused quartz. By contrast, PCS/HCS comprises a glass core surrounded by plastic cladding. The glass core is often vitreous silica, and the cladding is usually a silicone elastomer with a lower refractive index.

Applications requiring radiation energy near the visible wavelength spectrum are made from non-solarizing UV-grade and ultra-low OH-content NIR-grade fibers to reduce light absorption and prevent degradation of fibers over time. For spectroscopy-type applications, typical core diameters are 100, 200, 400, or 600 microns with an SMA standard termination. Thicker cores allow more light to be transferred, while the fibers are more rigid. It should be mentioned that optical fibers are also used for telecommunication purposes, which use a significantly smaller core – but this is not advantageous for spectroscopic applications.

Fiber Optic Cable

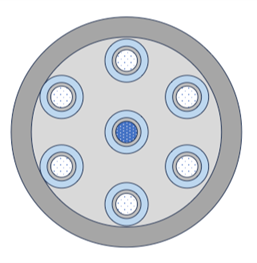

The core function of fiber optic probes involves delivering light to a sample or target area and collecting the resulting signal for analysis. The transmitted light interacts directly or indirectly with the sample (solid, liquid, or gas), which causes a change in the light beam that travels back to the detection system. The optical cable is made by packing several optical fibers (an assembly of fibers) into a tube and delivering or receiving the light from the probe body.

There are many advantages to using a fiber optical cable over a more traditional electronic cable composed of a wire assembly:

- They are resistant to harsh environments.

- The signals transmitted through optical fibers are immune to electromagnetic interference and can be transmitted long distances without significant loss.

- Since optical cables use light, the time for transmission is extremely fast compared to the latencies associated with electrical signals propagating through electronic conditioning circuitry.

- Optical setups can allow for probe placement farther away from the sample, while an equivalent electrical probe would require contact or very close proximity to a sample of interest for detection.

These advantages have created the demand for the use of fiber optic spectroscopy over the past few decades.

Because industrial fiber optic probes must withstand strenuous environments requiring robust cable construction, optical cable assemblies are loose-tube construction and protected by a stainless-steel mono coil armor with a PVC or Teflon outer sleeve.

Probe Body

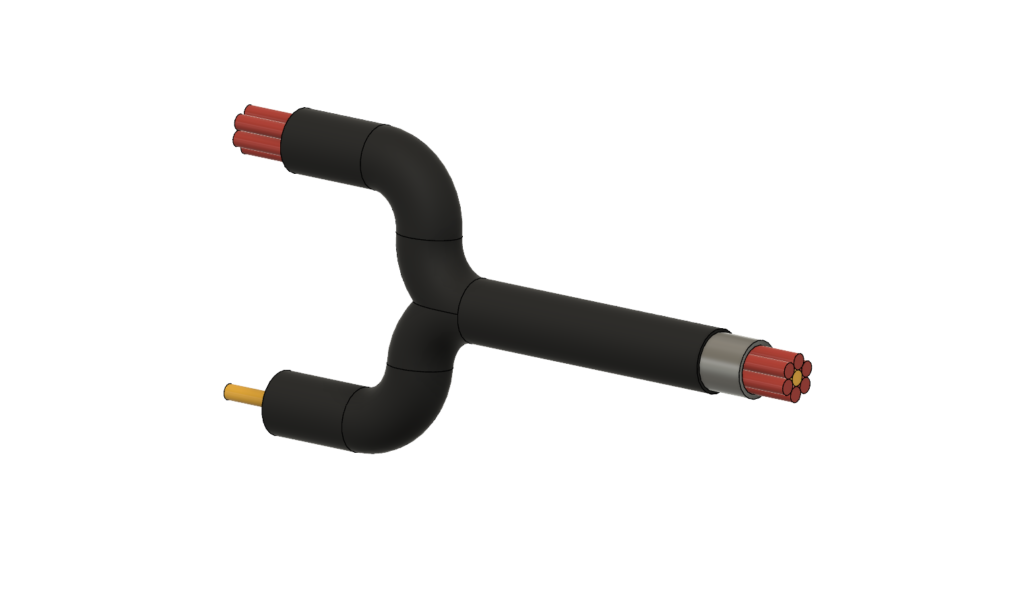

Probe bodies are made according to the sample and application (industrial process). Probe bodies are designed according to various parameters:

1. One must consider if the probe body needs to be in intimate contact with the sample (such as immersed in a tank or pipe) or be placed at a distance (non-contact) from the sample.

2. The application or objective (color, composition, or turbidity/haze measurement) must be considered.

3. The material’s characteristics (opaque, semi-opaque, translucent, transparent) must be considered.

Probe bodies direct, concentrate, or manipulate the incident light so the intensity of the response signal is optimized before it is transmitted to the detector. Probe bodies can be manufactured from many materials, the most common being stainless steel, aluminum, titanium, Hastelloy-C, or PEEK.

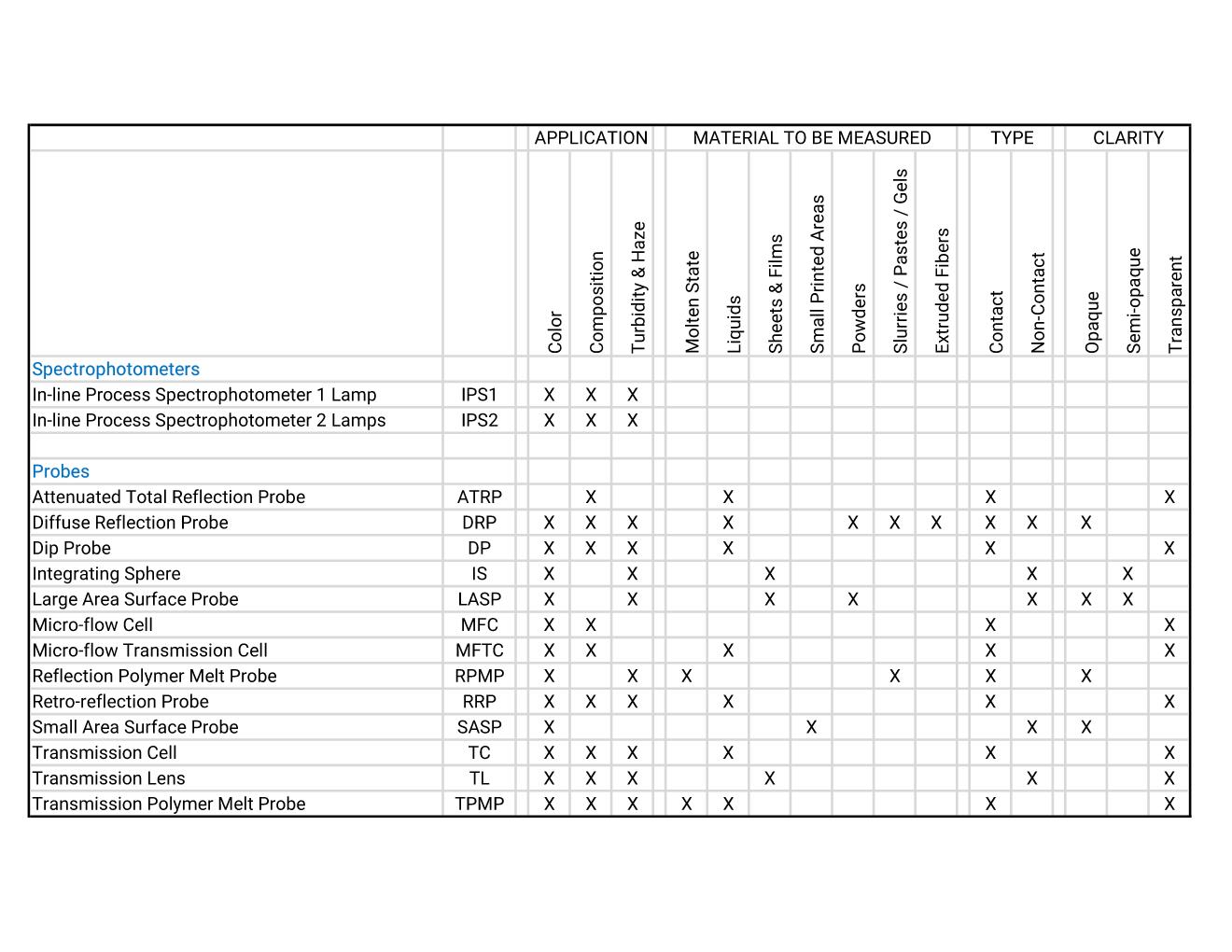

Probes for Different Applications

Equitech manufactures contact and non-contact probes for measuring real-time solids, liquids, slurries, pastes, gels, fibers, yarns, hot melts, and gases. The probes are specially designed to access difficult entry points and withstand harsh environmental conditions.

CONTACT US

Equitech Int’l Corporation

7711 Idlewild Road, Indian Trail, NC 28079

Tel +1-704-882-4624

[email protected]

equitechintl.com