ATTENUATED TOTAL REFLECTION PROBE For In-Line UV-Vis Measurement

INTRODUCTION

The high-throughput, rugged ATRP (Attenuated Total Reflection Probe) (Fig. 1) is ideal for use in an industrial process environment with the EquiSpec IPS (In-line Process Spectrophotometer). It can operate at temperatures from -30°C to 280°C and at pressures up to 82 bar (1200 psi). This outstanding performance is achieved by using Kalrez® O-ring seals.

The ATR Probe is a three-bounce design that affords a total path length of approximately 1.5 microns with a sapphire crystal. The sapphire allows response down to 250 nm in samples with an index of refraction up to 1.5, and offers excellent resistance to chemical attack. Cubic zirconia may be used in samples with an index of refraction up to 1.9. The fibers emerge from the probe’s rear in PVC-coated stainless steel armor. If needed, the armor can be sealed with Teflon® for high-temperature operation. An eight-inch extension tube is added to the probe’s rear to allow direct insertion into a process stream. The extension tube can be adapted to the customer’s process connection requirements.

APPLICATION

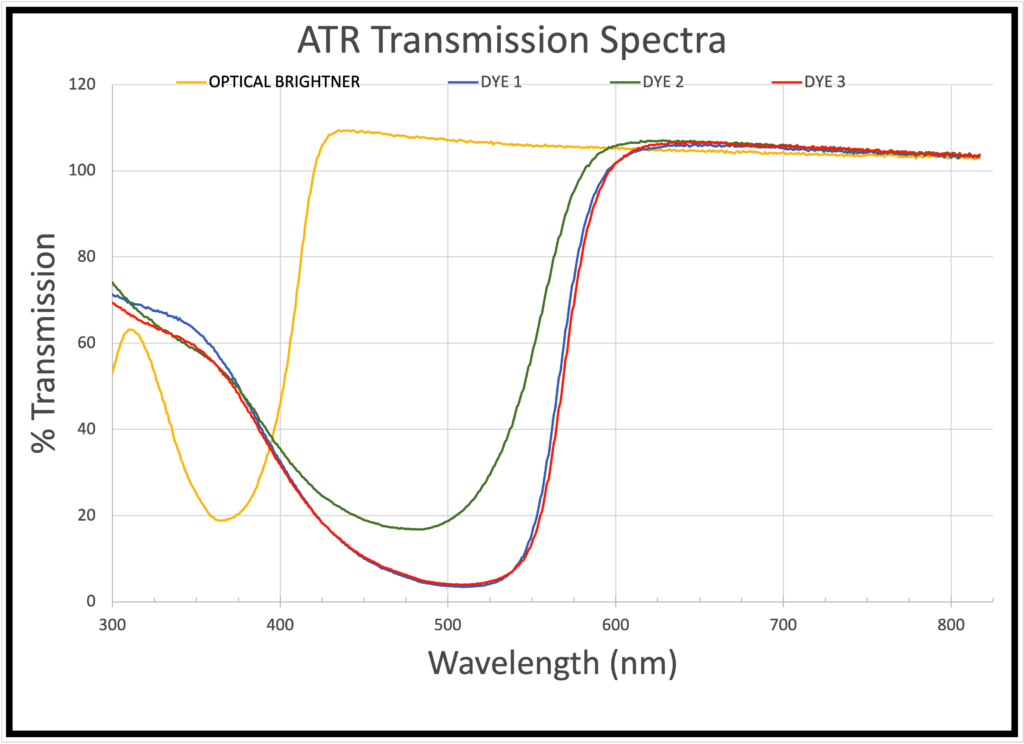

The ATR probe analyzes highly absorbing chromophores such as dyes and aromatic compounds (FIG. 2), minimizing or avoiding the need for diluting solvents making the technique ideal for continuous in-line analysis.

In the pharmaceutical industry, the EquiSpec IPS used with an ATR probe can provide real-time information on the crystallization process of active pharmaceutical ingredients (API), a critical step to ensure such process’s chemical and physical properties. Other applications for UV-Vis ATR spectroscopy are cleaning validation, dissolution rate testing, and reaction monitoring.

In the paper industry, the technique has been used to analyze hydroxide, sulfide, and carbonate in kraft liquors.

TECHNOLOGICAL INNOVATIONS

Equitech’s ATR Probe requires no internal optical elements other than the ATR crystal. This characteristic makes the probe simpler to manufacture and more rugged than is possible with a complex optical design. Furthermore, the probe combines illumination with detection to measure transmitted light in liquids with a very high optical density.

In addition, this design produces a more stable, flatter baseline and more linear response. The light-carrying optical fiber is a bundle of seven 200-micron core fused silica fibers arranged along an arc at the circumference of the ATR hemisphere. A matching seven-fiber bundle, set in an arc 180° opposite the input fibers, returns light to the detector.

Optical

| Path Length | 1.5 microns |

| ATR Material | Sapphire |

| Maximum Sample Index of Refraction | 1.5 |

| Optical Geometry | Refraction of the light rays by the Sapphire results in illumination at approximately 28° |

| Optical Fiber Type | 2 x NIR-7: 6 – (200 microns) fibers around 1 (200 microns) fiber |

| Fiber Packaging | PVC coated (80°C) armored fiber bundle. Teflon coated (220°C) armored fiber bundle |

| Fiber Length | 5 meters standard |

| Fiber Termination | SMA 905 |

Physical

| Body & Materials | 316 SS** |

| Body Dimensions | 247.7 mm (9.75”) length; 12.7 mm (0.5”) diameter |

| Seal Type | O-ring |

| Mounting | 12.7 mm (0.5”) compression fitting |

| Temperature Range | -20°C to 260°C |

| Maximum Pressure | 83 bar (1200 psi) |