IN-LINE PROCESS MEASUREMENT FOR pLASTIC COMPOUNDING

INTRODUCTION

Without additives, most polymers will fail quickly. Additives are chemicals added to the base polymer (resin) to improve processability and achieve the final product’s desired chemical and physical properties.

Plastics compounding aims to convert a base resin (such as PE, PP, PS, ABS, PVC, Nylon, etc.) into the plastic with desired properties.

Plastic compounding is a unit operation where the base polymer is mixed with such additives. The plastics compounding process has several steps, including determining the additives ratios, feeding, extruding, cooling, pelletizing, and blending the final pellets.

Plastic compounders produce a Masterbatch, a concentrated mixture of pigments and additives encapsulated into a carrier resin. Masterbatch is used for coloring plastics or imparting other properties to plastics (additives masterbatch).

EQUISPEC IPS

Equitech’s In-Line Process Spectrophotometer (IPS) makes possible continuous color measurement directly in the process.

The IPS comprises a spectrophotometer and an industrial touchscreen computer integrated into a NEMA4 stainless steel box. The IPS is designed and equipped specifically for use in the production environment. The IPS also contains a thermoelectric cooling and heating device to keep the temperature inside the box constant.

The IPS is triggered for measurement every 1 to 30 seconds allowing for 100% inspection of the plastics extrudate. The calibration of the spectrophotometer is explicitly designed for the operations’ demands and can be done without interrupting the production process.

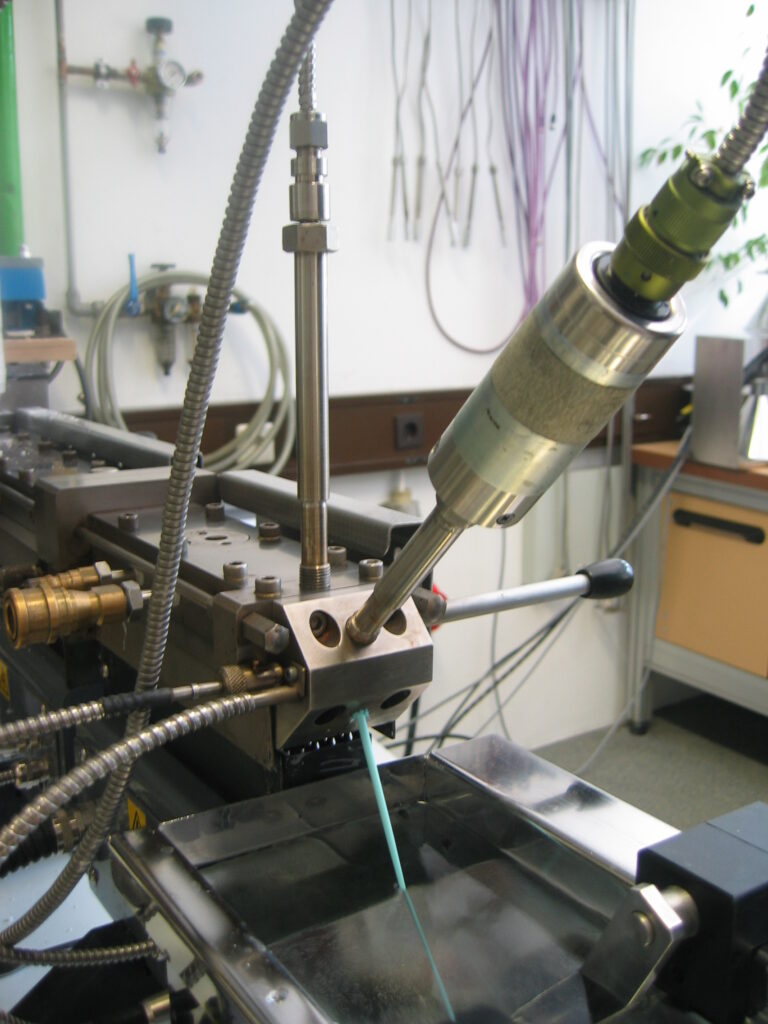

The IPS uses fiber optics and probes to illuminate the sample and transport the signal back to the analyzer.

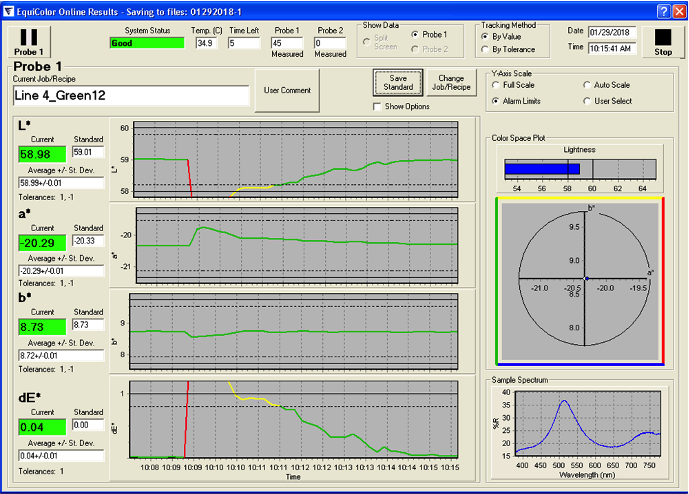

Illumination of the plastic melt through the sapphire window is achieved by six (6) circumferentially-positioned glass fibers, which convey the light of a xenon flash lamp. The reflection from the illuminated surface is detected by one center-positioned optical fiber. The spectrophotometer then interprets this reflected light. Color values such as L*, a*, b*, and others are calculated from this spectral curve and displayed as trend charts in EquiColor (Fig. 3).

OFF-LINE VS. CONTINUOUS MEASUREMENT

The typical procedure for off-line measurements:

- Manually take a sample from the process

- Send/take the sample to the laboratory

- Perform ‘off-line’ measurements in the lab

- Report the results to production

- Decide on a process adjustment

- Repeat the above five (5) steps if necessary

The delay between sampling and obtaining the results from the laboratory can be time-consuming. A significant disadvantage is that only a single measurement is generated in this period, and the quality of the color before and after the sampling point is unknown.

Complete documentation is possible with the in-line measurements taking place, and immediate intervention can occur when color variations occur. In addition, this method eliminates many steps of the offline process, and the measured results are available in real-time.

Continuous real-time measurement allows for confirmation to the operator that the extruded plastic has a consistent color that indicates that the product has been adequately mixed. Also, with the Equitech measurement, residence time can be determined.

USER BENEFITS

- Real-time information about process stability & quality

- Impact of speed changes on the quality of the extrusion

- Controlled color changes: start phase, end of a run

- Avoid off-specification batches & waste production

- Detection of dosage elevations

- Optimized recipe formulation & process design

CONTACT US

Equitech Int’l Corporation

7711 Idlewild Road

Indian Trail, NC 28079

Tel (704) 882-4624

[email protected]

equitechintl.com