In-line color measurement in Beverages

INTRODUCTION

When it comes to the consumption of beverages, color is, perhaps, one of the most critical factors in a consumer’s purchasing decision.

The food industry prepares beverages in batch or semicontinuous processes. Any change in the raw materials, particularly those carrying pigmentation properties such as fruits and grains, changes the appearance of the batch. This effect can be easily observed in products produced from natural ingredients such as beer, wine, dairy, sports drinks, fruit juices, etc. (FIG. 1)

The production of a consistent batch-to-batch color is paramount in the beverages industry because of regulations, branding, and consumer’s perception of the quality of the product. As a consequence, the color of each batch must be adjusted to an accepted standard to achieve such consistency.

Beverages can be opaque, translucent, or transparent because natural ingredients induce a wide variability of their optical properties. This factor causes the measurement of color in real-time to be quite challenging (FIG. 2)

THE EQUISPEC™ (IPS)

The in-line process control system is designed and equipped specifically for use in the production environment where the ambient conditions can be dusty, vary in temperature, be subject to vibration, etc.

The dual-channel spectrometer is integrated into a NEMA4 box (FIG. 3) with an industrial computer and a touch screen. The box also contains a thermoelectric cooling and heating device to eliminate the influences from ambient conditions by keeping the temperature inside the box constant.

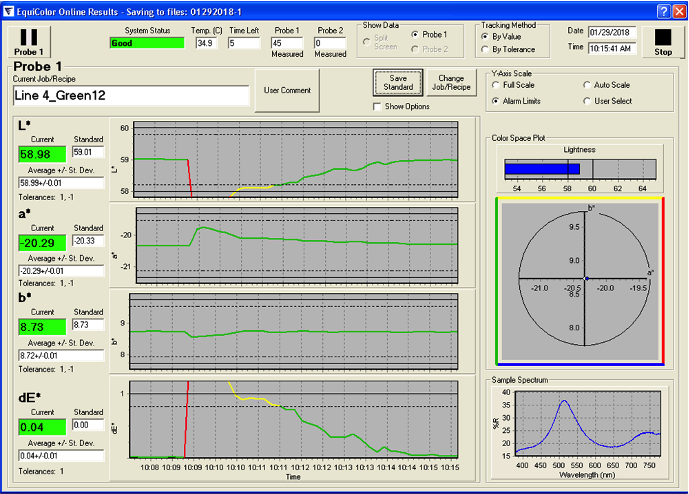

A Diffuse Reflectance Probe (DRP), Retro Reflection Probe (RRP), or Attenuated Total Reflection Probe (ATRP) is used to measure color in the beverage in reflection or transmission. Fiber optics convey the light of a xenon flash lamp to a sapphire window placed at the tip of the probe. One or several optical fibers detect the reflected or transmitted light returning from the sample. The spectrophotometer then interprets this reflected light. Color values such as L*, a*, b*, and others are calculated from this spectral curve and displayed as trend charts in EquiColor (FIG. 4).

The spectral range is 380-780 nm (resolution 1 nm). The EquiSpec IPS is triggered for measurement every 1 to 30 seconds allowing for 100% inspection. The calibration of the spectrophotometer is explicitly designed for the operation’s demands and can be done without interrupting the production process.

OFF-LINE VS. CONTINUOUS MEASUREMENT

The typical procedure for off-line measurements:

- Manually take a sample from the process

- Send/take the sample to the laboratory

- Perform ‘off-line’ measurements in the lab

- Report the results to the production department

- Decide on a process adjustment

- Repeat the above five (5) steps if necessary

The delay between sampling and obtaining the results from the laboratory can be time-consuming. A significant disadvantage is that only a single measurement is generated in this period, and the quality of the color before and after the sampling point is unknown.

IN-LINE COLOR MEASUREMENT BENEFITS

Complete documentation is possible with the in-line measurements taking place directly in the food, and immediate intervention can occur when color variations occur. In addition, this method eliminates many steps of the off-line process, and the measured results are available in real-time.

Continuous real-time measurement allows for confirmation to the operator that the beverage has a consistent color indicating that the product has been adequately mixed and processed.

- Real-time information about process stability & quality

- Controlled color changes: start phase, end of a run

- Avoid off-specification batches & waste production

- Detection of dosage elevations

- Optimized recipe formulation & process design

CONTACT US

Equitech Int’l Corporation

7711 Idlewild Road

Indian Trail, NC 28079

Tel (704) 882-4624

info@equitechintl.com

equitechintl.com