IN-LINE Color Measurement of Decking & Fencing

INTRODUCTION

Decks and Fences are extruded products made primarily from aluminum, pressure-treated wood, polyvinyl chloride (PVC) resin, and composite materials that combines plastic with wood fibers. Decks and fences are popular additions to residential houses.

PVC and composite-made Decking and Fencing are available in many colors and textures. However, because they are normally exposed to the elements, they will fade over time. Most manufacturers offer extended warranties that their products are fade resistance over that period of time. While light and pastel colors can easily meet this hurdle, darker colors tend to fade more than lighter ones.

COLOR MEASUREMENT

Color values are good indicators of process quality. All parameters in the production process (temperature, pressure, production speed, feeders, pumps, etc.) have a direct impact on color values.

Equitech’s In-Line Process Spectrophotometer (IPS) (FIG. 2) makes possible continuous color measurement directly in the process.

PROCESS MONITORING

Decking and Fencing are manufactured in an extrusion or a co-extrusion process that can suffer from variabilities caused by both the raw materials and the equipment. Raw materials, such as PVC, titanium dioxide, pigments, fillers, lubricants, wood fiber, etc., change from lot to lot affecting the composition of the final product.

Extruders, feeders, heaters, pullers, blenders, vacuum pumps, and other equipment used in the process, directly affect process parameters such as temperature, pressure, production speed and ultimately, color.

A continuous process that suffers from such variabilities cannot be adequately monitored by a sampling ‘batch method’ that takes a long period of time and provides no accountability for what happens in the process in between sampling points.

The delay between taking a sample and possibly adjusting the process translates into significant waste of material and energy. Worse yet, with the traditional batch method only a single measurement is generated during each sampling period with no accountability for what happens in the process in between sampling points. The process is essentially running blind.

EQUISPEC IPS

The IPS consists of a spectrophotometer and a touch screen industrial computer integrated in a NEMA4 stainless steel box. The IPS is designed and equipped specifically for use in the production environment. The IPS also contains a thermoelectric cooling and heating device to keep the temperature inside the box at a constant level; important when measuring color.

The IPS uses fiber optics and probes to illuminate the sample and transport the signal back to the analyzer. For Decking and Fencing, manufacturers have a choice of probes for contact and non-contact measurement.

CONTACT MEASUREMENT

The Reflection Polymer Melt Probe (RPMP) is used to measure color directly in the polymer melt before the extrudate is formed.

The RPMP is installed in the exit (adapter) of the extruder using a ½”-20 UNF thread (type Dynisco®) where it enters in direct contact with the melt stream.

The RPMP consists of the threaded body, optical fibers and sapphire lens. The sapphire lens on the tip of the probe is the observation window and is very well suited to the harsh extrusion conditions (high temperature, pressure and friction). The self-cleaning function of the sapphire is ensured by the shear force of the material flow.

NON-CONTACT MEASUREMENT

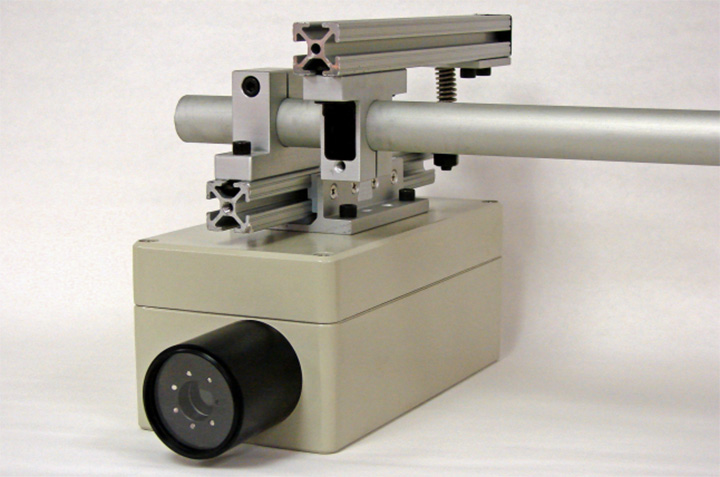

The Large Area Surface Probe (LASP) is mounted over the extruded profile where it measures color without contacting the product. The probe measures the diffusely scattered component of the light reflected from the profile while ignoring the specular components. Because it is ‘blind’ to the specular reflection, this probe may be used to measure the color of a glossy surface, while being insensitive to the ‘gloss’ or ‘shine’.

CONTACT US

Equitech Int’l Corporation

7711 Idlewild Road

Indian Trail, NC 28079

Tel (704) 882-4624

[email protected]

equitechintl.com

USER BENEFITS

- Comprehensive quality audit trail of final product

- Feedback loop for L* closed loop control via feeder

- Impact of speed changes on the quality of the extrusion

- Avoidance of off-spec batches

- Adjustment and fine tuning of recipes

- Reduce costs – higher ROI