IN-LINE COLOR MEASUREMENT OF PLASTIC PROFILES

PLASTICS EXTRUSION

Plastic extrusion is the transformation of a thermoplastic material or resin into a shape that can be used as produced or that can be further converted into a usable product. The plastic extrusion process is used to produce items

such as films, sheets, coatings, pipes, tubes, fencing & deck railings, window frames, weather-stripping, straws, and wire insulation to name a few. Typical plastic materials that are used in extrusion include, but are not limited to, acrylonitrile butadiene styrene (ABS), polyamides (PA), polycarbonate (PC), polyethylene (PE), polypropylene (PP), acetal, acrylic, polystyrene (PS), polyvinyl chloride (PVC), and polypropylene (PP).

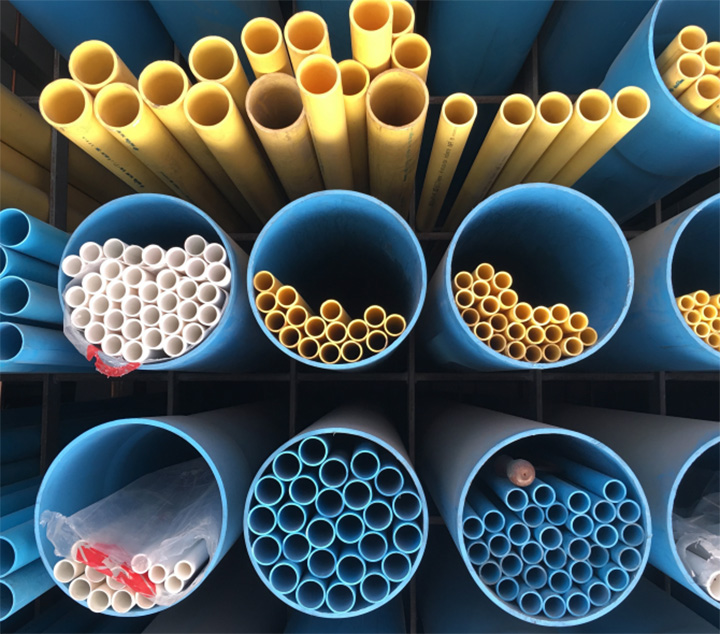

PIPE

Pipe is formed when plastics are extruded through an inline die, cooled in a water bath, and either cut or coiled. The most commonly used pipe materials are polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), crosslinkable polyethylene (PEX), and high-density polyethylene (HDPE).

Rigid pipes are commonly used in building and construction for drain, waste and vent applications, and are processed in twin-screw extruders; HDPE pipes are used for a wide range of industrial, electrical and drainage applications. PVC can be made softer and more flexible by the addition of plasticizers.

TUBING

Tubing is a term used to describe a small diameter pipe that is flexible. Typical plastic materials that are used to make flexible plastic tubing include polyamide (PA) or nylon, polyethylene (PE), fluorinated ethylene propylene (FEP), polyvinylidene fluoride (PVDF) and polyurethane (PU). Flexible tubing is used for agricultural drainage, electrical conduits, drinking straws, dip tubes in spray.

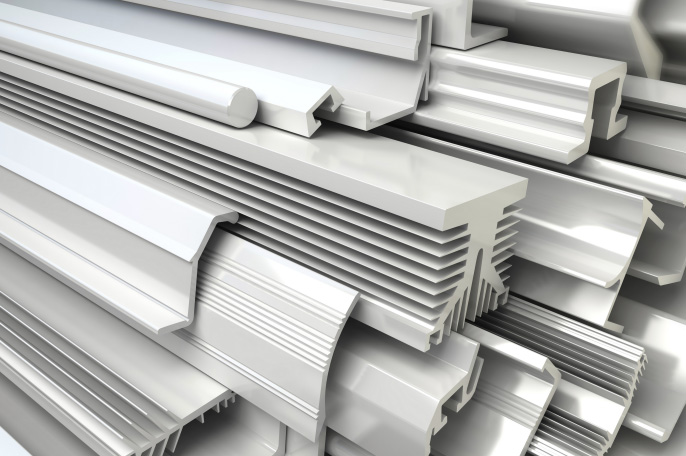

PROFILE

An important application of plastic extrusion is the production of profiles. Plastic extrusion profiles are used for windows, doors, and siding. Typical plastic materials that are used in profile extrusion include acrylics, butyrate, fiberglass composites, nylon, low density polyethylene (LDPE), high density polyethylene

(HDPE), polystyrene, polyurethane (PU), polyvinyl chloride (PVC) and wood-fiber composites (WPC).

INNOVATION

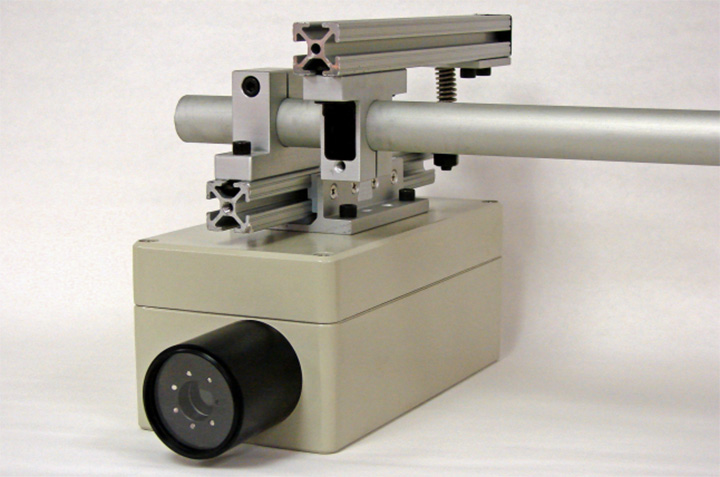

Color values are good indicators of process quality. All parameters in the production process (temperature, pressure, production speed, feeders, pumps, etc.) have a direct impact on color values. Equitech’s In-Line Process Spectrophotometer (IPS) makes possible continuous color measurement directly in the process. The IPS consists of a spectrophotometer and

a touch screen industrial computer integrated in a NEMA4 stainless steel box. The IPS is designed and equipped specifically for use in the production environment. The IPS also contains a thermoelectric cooling and heating device to keep the temperature inside the box at a constant level.

The IPS uses fiber optics and probes to illuminate the sample and transport the signal back to the analyzer. For plastic extrusion profiles, customers have a choice of probes for contact or non-contact measurement.

IN-LINE & REAL-TIME MEASUREMENT

For those customers wanting to measure directly in the polymer melt before the extrudate is formed, Equitech offers the Reflection Polymer Melt Probe (RPMP). The RPMP is installed in the exit (adapter) of the capstock extruder using a ½”-20 UNF thread (type Dynisco®) where it enters in direct contact with the melt stream. The RPMP consists of the threaded body, optical fibers and sapphire lens. The sapphire lens on the tip of the probe is the observation window and is very well suited to the harsh extrusion conditions (high temperature, pressure and friction). The self-cleaning function of the sapphire is ensured by the shear stress of the material flow.

For those customers that prefer to measure color directly on the extruded shape, Equitech offers the Large Area Surface Probe (LASP). The LASP can be

mounted over the extruded vinyl siding. It measures color without contacting the product. The probe measures the diffusely scattered component of the

light reflected from the vinyl siding while ignoring the specular components. Because it is ‘blind’ to the specular reflection, this probe may be used to

measure the color of a glossy surface, while being insensitive to the ‘gloss’ or ‘shine’.

USER BENEFITS

•Comprehensive quality audit of final product

•Feedback loop for L* closed loop control via feeder

•Impact of speed changes on the quality of the extrusion

•Controlled color changes: start phase, end of run

•Avoidance of off-spec batches

•Adjustment and fine tuning of recipes

•Reduce costs – higher ROI

CONTACT US

Equitech Int’l Corporation

7711 Idlewild Road, Indian Trail, NC 28079

Tel +1-704-882-4624

[email protected]

equitechintl.com