Understanding What a Spectrophotometer Is and How it Works

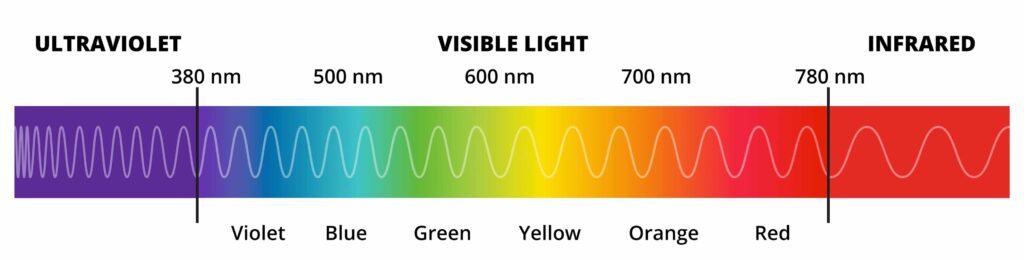

Scientists use spectroscopy—the study of matter’s absorption and emission of electromagnetic radiation—to investigate materials and their properties. The electromagnetic radiation spectrum is divided into ranges of wavelengths. For example, ultraviolet (UV) light ranges from approximately 100 nanometers (nm) to 400 nm. Visible light has wavelengths from 400 nm (violet color) to 780 nm (which appears red in color). Infrared (IR) radiation has wavelengths from about 780 nm to 1 mm.

What is a spectrophotometer?

Spectrophotometers are analytical instruments used to measure the intensity of electromagnetic energy at each wavelength of light in a specified region. This characteristic “signature” can be used to identify and quantify different molecular structures and chemical species within a material.

Different instruments use different parts of the electromagnetic spectrum. For example, an IR spectrophotometer uses wavelengths in the IR range, and a UV-Vis spectrophotometer uses wavelengths in the UV and visible range.

Types of spectrophotometers

Spectrophotometers come in different types for different uses. With a benchtop instrument, a sample is brought to the lab and prepared to be inserted into the device. Portable or handheld spectrophotometers can be brought wherever a sample measurement needs to be made.

In-line spectrophotometers have unique probes designed to be used in the processing line so that the material goes past the probe. For example, a probe can be inserted into a liquid process stream or mounted over a conveyor belt. An in-line probe can collect data points in a continuous stream of samples. Measurements are made in “real time,” without the time delay that occurs when a sample must be taken to a lab.

How does a spectrophotometer work?

A spectrophotometer has an energy source (e.g., a lamp) that focuses light onto the sample. When light strikes a material, some energy is reflected, some is transmitted, and some is absorbed. A detector in the spectrophotometer then receives and measures the reflection, transmission, or absorption from the partial energy received based on the measurement location. For an in-line spectrophotometer, an additional component is a fiber optic probe that carries the light from the lamp to the sample and returns the light from the sample to the detector.

Another component of all spectrophotometers is a spectrometer—an optoelectronic device that converts the detected light energy into digital data. These data are analyzed using mathematical algorithms within the spectrophotometer’s central processing unit (CPU) and presented to the user as numbers and graphs that can be used to make decisions.

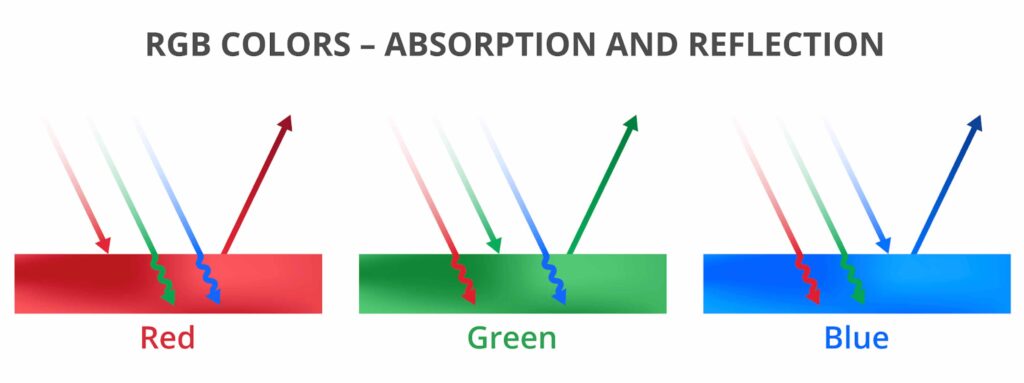

To measure the color of a material, a beam from the light source strikes a sample. The wavelength corresponding to the exact color of the sample will be reflected, while all the other wavelengths will either pass through or be absorbed. The detector, operating in reflectance mode, receives the wavelengths that are reflected.

What does a UV-Vis spectrophotometer measure?

A UV-Vis spectrophotometer is a sophisticated instrument that can measure different properties of a material, such as color. The instrument detector collects the spectrum from the sample, and a software program correlates this spectrum to color values, such as CIE L*, a*, b*. Color is a critical aspect of product quality in many applications, including plastic parts (e.g., siding or flooring), plastics masterbatches, paint, inks, textiles, coatings, and food.

A UV-Vis spectrophotometer can also measure turbidity in fluids. Suspended particles in the fluid scatter light from the instrument’s light source. The instrument detector then detects and quantifies the scattered light compared to a standard. Turbidity is a crucial measure in beverages, industrial processes, pharmaceutical manufacturing, chemical manufacturing, and environmental monitoring of water. Similarly, light coming through a translucent plastic solid is scattered, and a spectrophotometer can detect and quantify the amount of scattering, which is reported as a percentage of haze. Haze is a critical quality attribute in thin plastic films.

A UV-Vis spectrophotometer can measure concentrations of chemicals in gases, liquids, solids, or slurries. An analyzer compares the spectra collected by the detector to a reference and uses this information to measure concentration. The comparison can be a simple single wavelength or a complex chemometric model.

A UV-Vis spectrophotometer can measure layer thickness in films or coatings. When light is passed through the sample, it is refracted—i.e., reflected at an angle—at the boundary line between the layers. The thickness of the layer can then be calculated from this interference spectrum and the index of refraction of the materials.

Functions of an in-line UV-Vis spectrophotometer

An in-line UV-Vis spectrophotometer is ideal for real-time process monitoring, primarily to determine whether product quality remains within the specifications. If the product goes outside the specifications, the process operator can make a correction. Because the measurement from an in-line instrument is made in real-time, this correction can be made more quickly than if the operator had to wait for the result from a lab sample. In addition, the data points from an in-line system can be recorded to document the process and product quality.

Equitech’s Inline Process Spectrophotometer (IPS) measures color, haze, or another product quality specification and activates an alarm if the measurement exceeds the specification range. In addition, Equitech’s real-time quality assurance software provides a report of the results of a production run.

Contact Equitech’s experts to learn more about how an in-line process spectrophotometer can benefit your operation.